Our sister concern, the Eden Innovations LLC, USA has engineered through a pyrolysis process some very valuable byproducts namely Carbon Nanotubes (CNT) and Carbon Nanofibers (CNF). The uses of this Nanomaterial are endless, giving them great value. Eden India wants to market the Nanomaterial to use it for its applications in different areas like conductive paints, conductive plastics, thermoplastics, cement & RCC, Li-Ion batteries etc.

Carbon Nanotubes boost surface abrasion resistance and reduce permeability while improving strength properties (e.g., compressive, flexural, and tensile) like no other product in the market today.

To make things work Eden Innovations India Pvt Ltd has also developed an admixture concrete (named EdenCrete®) through their extensive research and development. It is named EdenCrete® admixture.

EdenCrete® is Eden’s 100% owned, proprietary carbon-strengthened concrete additive, one of the primary target markets for which is improving the performance of concrete used in the construction and maintenance of concrete roads, bridges and other infrastructure. Additionally, it has potential usage in a range of other applications including high-rise building construction, marine and coastal applications, water storage and pipelines, and pre-fabricated concrete structures and products.

Improved resistance to abrasion helps prevent the surface of the concrete from wearing away and being damaged from impact.

Higher flexural strength helps to prevent cracking in suspended bridge girders and decks, elevated slabs, and thin-overlay applications

Reduced shrinkage and resistance to cracking improves durability and extends service-life

Reduced permeability helps prevent the ingress of moisture, alkali-silica reaction, sulfate-attack, corrosion of reinforcement, and freeze/thaw.

Higher tensile strength helps minimize cracking in reinforced concrete applications

Improved compressive strength may allow for a reduction in total cementitious while still meeting design specifications

Improved durability and performance will extend the time until repair or replacement is necessary, reducing life-cycle costs

Improved resistance to scaling extends the durability and service life of concrete exposed to deicer chemicals

Accelerates finishing as the cement paste rises to the surface with minimal effort, reducing the time and personnel required to complete the job

This admixture significantly improves tensile and flexural strength of concrete. It has been proven in both lab and field tests to offer these strength advantages without compromising on compressive strength, permeability, or corrosion resistance.

When added to concrete mixtures, EdenCrete’s carbon nanotubes fill in spaces at the nanoscopic level between the hydrated cement particles. When concrete cures, instead of leaving porous voids that would allow water to penetrate or cracks to develop, these nanotubes create millions of flexible, strong carbon bridges throughout the structure.

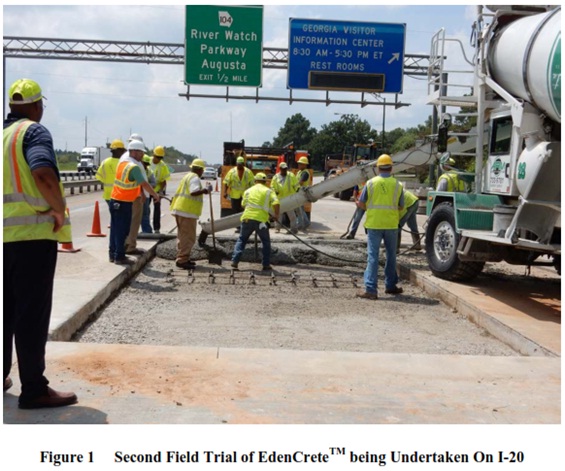

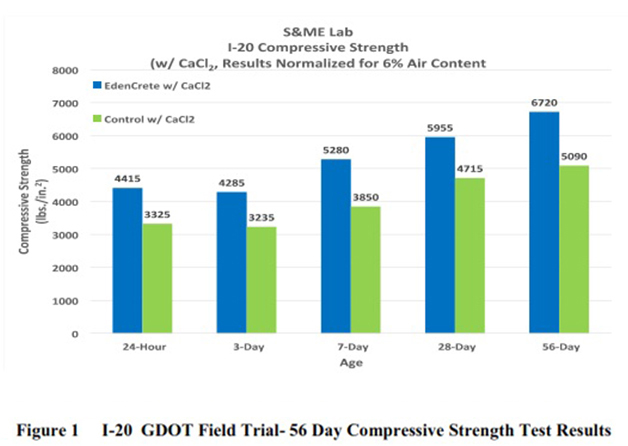

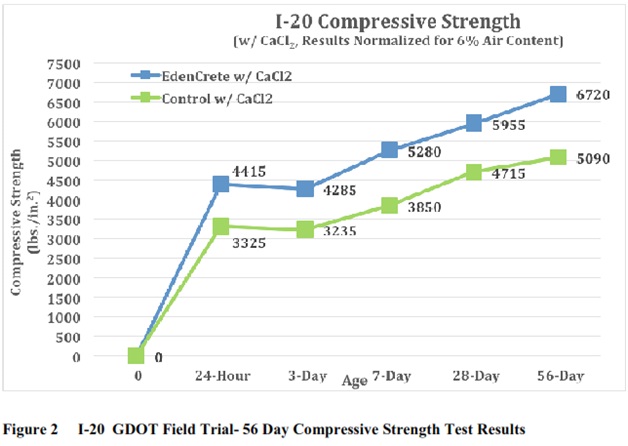

A field trial of EdenCrete® enriched concrete was undertaken on the Interstate Highway I-20 in Augusta near the border between Georgia and South Carolina. This field trial involved the pouring of an additional 14 cubic yard concrete slab that abuts the first slab that was laid with EdenCrete® enriched concrete in the first field trial on 11August 2015 as part of a planned maintenance programme on I-20 (see Figures 1 and 2).

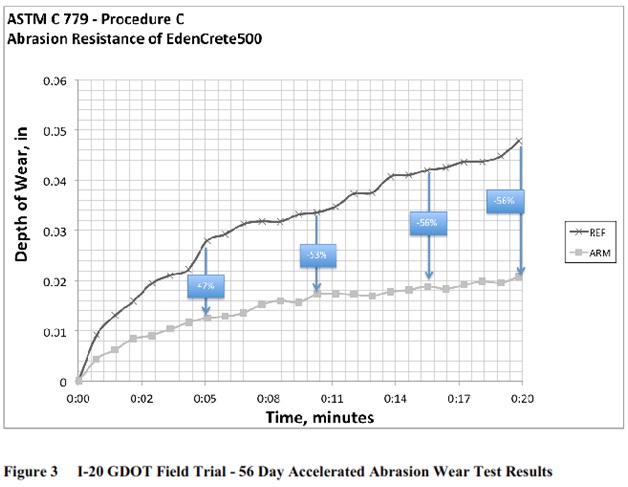

These accelerated abrasion tests, carried out in accordance with AS™ standard C779 showed a very impressive 56% reduction in the depth of wear in the concrete that had been enriched with EdenCrete®.

These trials imperically establish that EdenCrete® has the potential of superior performance and commercial benefits for its use on future highway (and other infrastructure), its maintenance and construction programmes.